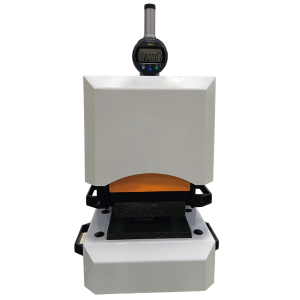

Semi-automatic PPG Thickness Gauge

PPG is used to measure the thickness of pouch batteries and battery cells, and can also detect various non-battery flexible sheet products. It uses weights to counterweight, and has the characteristics of simple operation, stable output pressure and accurate measurement.

1. Put the battery into the test platform, set the force value and other parameters;

2. Press the start button with both hands at the same time, and the test platen will start the pressure test;

3. When the test is completed, the test platen is automatically lifted;

4. The test is complete after removing the battery.

1. Measuring sensor: optical linear scale

2. Controller: independently developed by Handing

3. Body: white spray paint.

4. Materials: aluminum, steel, marble.

5. Cover: sheet metal.

|

S/N |

Item |

Configration |

|

1 |

Effective test area |

L200mm × W150mm |

|

2 |

Thickness range |

0-30mm |

|

3 |

Working distance |

≥50mm |

|

4 |

Reading resolution |

0.0005mm |

|

5 |

Flatness of marble |

0.003mm |

|

6 |

Measurement accuracy |

Put a 5mm standard gauge block between the upper and lower platens, and measure 5 points evenly distributed in the platen. The fluctuation range of the current measured value minus the standard value is ±0.015mm. |

|

7 |

Repeatability |

Put a 5mm standard gauge block between the upper and lower platens, repeat the test at the same position 10 times, and its fluctuation range is ±0.003mm. |

|

8 |

Test pressure range |

500-2000g |

|

9 |

Pressure method |

Use weights to pressurize |

|

10 |

Work beat |

8 seconds |

|

11 |

GR&R |

<10% |

|

12 |

Transfer method |

Linear guide, screw, stepper motor |

|

13 |

Power |

12V/24V |

|

14 |

Operating environment |

Temperature:23℃±2℃ Humidity:30~80% |

|

Vibration:<0.002mm/s,<15Hz |

||

|

15 |

Weigh |

45kg |

|

16 |

***Other specifications of the machine can be customized. |

|

Each of our equipment has the following information when it leaves the factory: production number, production date, inspector and other traceability information.

Hiwin, TBI, KEYENCE, Renishaw, Panasonic, Hikvision, etc. are all our accessories suppliers.

Our equipment has an average lifespan of 8-10 years.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top