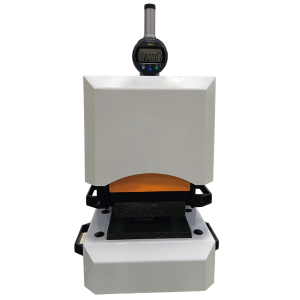

PPG automotive power battery thickness measuring machine

PPG-645SA5000N is used to measure the thickness of aluminum shell battery and automobile power battery. It adopts servo motor to pressurize, and has the characteristics of simple operation, stable output pressure and accurate measurement.

1 Turn on the computer;

2 Turn on the instrument;

3 Open the software;

4 Initialize the instrument and return to the zero position;

5 Put the standard gauge block into the equipment for calibration;

6 Set the pressure value and other parameters;

7 Start the measurement.

1 Device main body:

1.1) Electric control cabinet: power box, pressure sensing system, grating data control system, motor control system;

2.1) Pressurization method: the servo motor drives the up and down movement of the linear electric cylinder, thereby driving the upper platen of the thickness gauge, and then the force value signal set by the pressure sensor gives the precise value of the motor to control the pressure and grating of the upper and lower platens. displacement data.

2 Fixtures:

2.1) Upper and lower platen platform: the material is insulating material and will not conduct electricity, and the battery test product can be directly squeezed downward, so as to achieve the preset force value of the product or the actual measured force value of the product;

2.2) Numerical acquisition system: use a non-contact high-precision metal patch grating ruler with a resolution of 0.5um. Under the condition of motion pressure test, the thickness change data of the product is automatically recorded by the PPG software and imported into the data report to generate the customer system;

2.3) Safety grating: The human safety grating is installed at the entrance of the upper and lower platens to avoid personal hazards caused by personnel operating errors or failing to leave the platen in time. The safety grating will therefore automatically stop the machine in time.

|

S/N |

Item |

Configration |

|

1 |

Effective test area |

L600mm × W400mm |

|

2 |

Thickness range |

0-30mm |

|

3 |

Working distance |

≥50mm |

|

4 |

Reading resolution |

0.0005mm |

|

5 |

Flatness of marble |

0.005mm |

|

6 |

Measurement accuracy |

Put a 5mm standard gauge block between the upper and lower platens, and measure 5 points evenly distributed in the platen. The fluctuation range of the current measured value minus the standard value is ±0.04mm. |

|

7 |

Repeatability |

Put a 5mm standard gauge block between the upper and lower platens, repeat the test at the same position 10 times, and its fluctuation range is ±0.02mm. |

|

8 |

Test pressure range |

0-5000N |

|

9 |

Pressure method |

Use servo motor to provide pressure |

|

10 |

Work beat |

60-120 seconds |

|

11 |

GR&R |

<10% |

|

12 |

Transfer method |

Linear guide, screw, servo motor |

|

13 |

Power |

AC 220V 50HZ |

|

14 |

Operating environment |

Temperature:23℃±2℃ Humidity:30~80% |

|

Vibration:<0.002mm/s,<15Hz |

||

|

15 |

Weigh |

250kg |

|

16 |

***Other specifications of the machine can be customized. |

|

BYD, Pioneer Intelligence, LG, Samsung, TCL, Huawei and other companies are our customers.

Hiwin, TBI, KEYENCE, Renishaw, Panasonic, Hikvision, etc. are all our accessories suppliers.

The accessories provided by our suppliers must meet the quality standard and the delivery time standard.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top