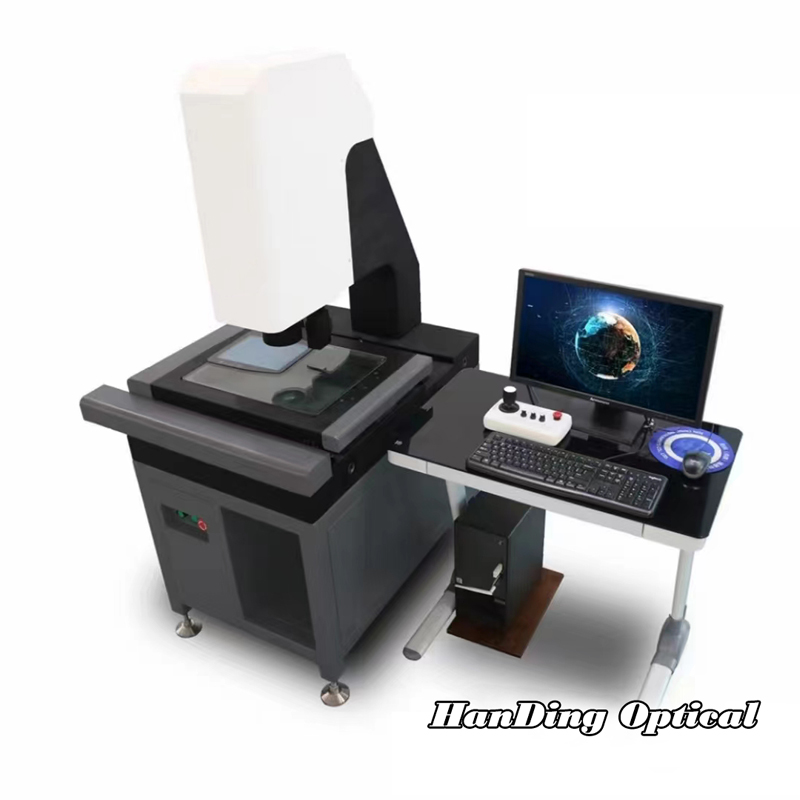

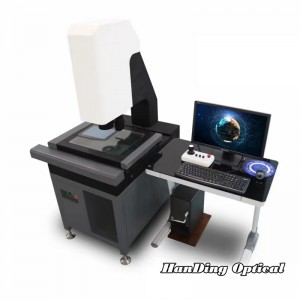

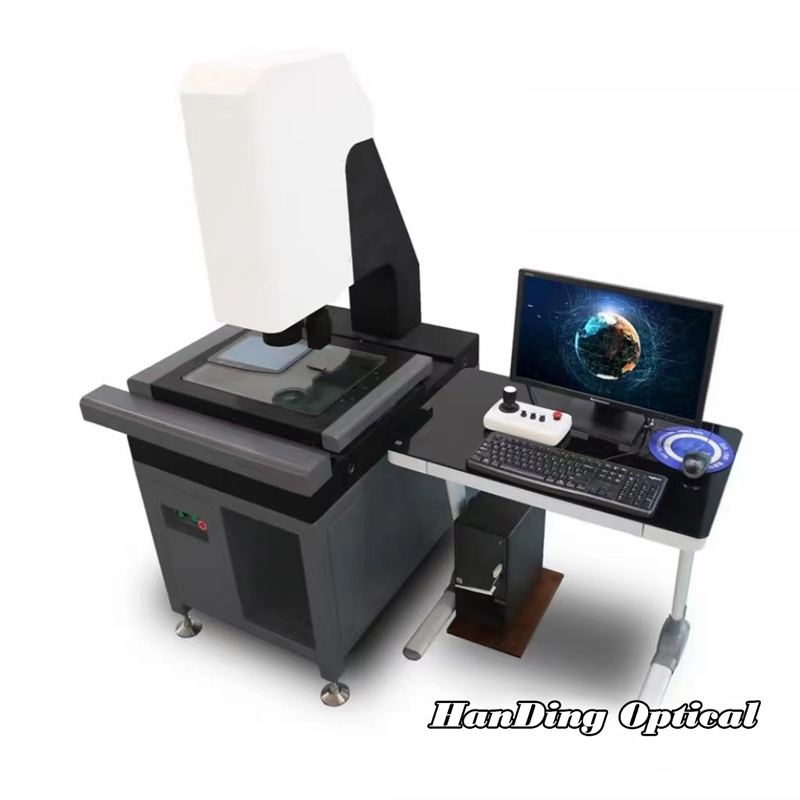

E-series Automatic Vision Measuring Machine

|

Model |

HD-322E |

HD-432E |

|

X/Y/Z range(mm) |

300×200×200 |

400×300×200 |

|

Workbench load(kg) |

25kg |

|

|

Transmission type |

High precision cross drive guide and polished rod |

|

|

Optical scale resolution |

0.001mm |

|

|

X/Y measurement accuracy |

≤3+L/200(μm) |

|

|

Camera |

TEO HD color industrial camera |

|

|

Lens |

Auto zoom lens, optical magnification: 0.7X-4.5X, image magnification: 24X-190X |

|

|

Software function |

Image software: it can measure points, lines, circles, arcs, angles, distances, ellipses, rectangles, continuous curves, tilt corrections, plane corrections, and origin setting. The measurement results display the tolerance value, roundness, straightness, position and perpendicularity. The degree of parallelism can be directly exported and imported into Dxf, Word, Excel, and Spc files for editing which is suitable for batch testing for customer report programming. At the same time, part of and the entire product can be photographed and scanned, and the size and image of the entire product can be recorded and archived, then the dimensional error marked on the picture is clear at a glance. | |

|

Warranty |

12Months |

|

|

Illumination system |

3 Ring LED Surface Light and White Parallel Contour Light |

|

|

Overall dimension(L*W*H) |

1100×700×1650mm |

1350×900×1650mm |

|

Weight(kg) |

200kg |

240kg |

|

Power supply |

AC220V/50HZ AC110V/60HZ |

|

|

Computer |

Customized computer host |

|

|

Display |

Philips 24 inches |

|

① Temperature and humidity

Temperature: 20-25℃, optimal temperature: 22℃; relative humidity: 50%-60%, optimal relative humidity: 55%; Maximum temperature change rate in the machine room: 10℃/h; It is recommended to use a humidifier in dry area, and use a dehumidifier in humid area.

② Heat calculation in the workshop

·Keep the machine system in the workshop operating in the optimum temperature and humidity, and the total indoor heat dissipation must be calculated, including the total heat dissipation of indoor equipment and instruments (lights and general lighting can be ignored)

·Heat dissipation of human body: 600BTY/h/person

·Heat dissipation of workshop: 5/m2

·Instrument placement space (L*W*H): 3M ╳ 2M ╳ 2.5M

③ Dust content of air

The machine room shall be kept clean, and the impurities greater than 0.5MLXPOV in the air shall not exceed 45000 per cubic foot. If there is too much dust in the air, it is easy to cause resource read and write errors and damage to the disk or read-write heads in the disk drive.

④ Vibration degree of machine room

The vibration degree of machine room shall not exceed 0.5T. Machines that vibrate in the machine room shall not be placed together, because the vibration will loosen the mechanical parts, joints and contact parts of the host panel, resulting in abnormal operation of the machine.

Receiving orders - purchasing materials - full inspection of incoming materials - mechanical assembly - performance testing - shipping.

Assembly time: Linear encoders are in stock, 3 days for manual machines, 5 days for automatic machines, 25-30 days for large stroke machines.

Yes, we require a MOQ of 1 set for all equipment orders and 20 sets for linear encoders.

Each of our equipment has the following information when it leaves the factory: production number, production date, inspector and other traceability information.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top