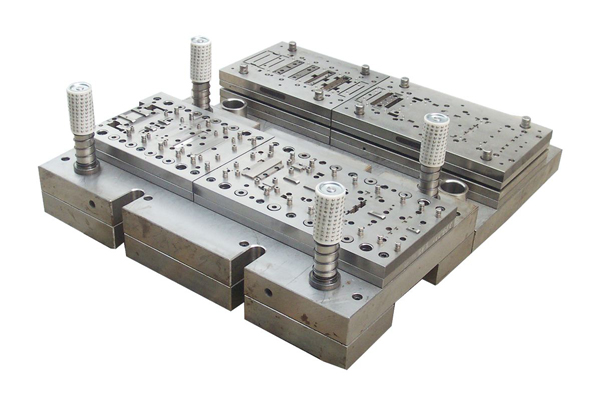

The scope of mold measurement is very wide, including model surveying and mapping, mold design, mold processing, mold acceptance, inspection after mold repair, batch inspection of mold molded products and many other fields that require high-precision dimensional measurement. The measurement objects are mainly multiple geometric quantities or geometric tolerances, which have certain requirements on the equipment. For molds with fine structure and small size, the traditional contact type three-coordinate probe has low efficiency and is not suitable for such workpiece inspection. The vision measuring machine can clearly observe the details of the mold with the help of the zoom lens, which is convenient for precision measurement tasks such as defect and size inspection.

Molded parts are characterized by a large number and high requirements for measurement efficiency. Traditional contact-type three-coordinate measuring machines, articulated arm measuring machines, large-size laser trackers and other instruments are also widely used in the field of mold measurement, but in the face of fine-structured, thin-walled workpieces, tiny injection molded parts, and batch rapid measurement , there is no good solution. With the help of the CCD area array sensor and the characteristics of non-contact measurement, the vision measuring machine can efficiently complete the measurement of the workpiece that cannot be contacted, easily deformed, and has a small shape. In this regard, the vision measuring machine has absolute advantages.

Post time: Oct-19-2022