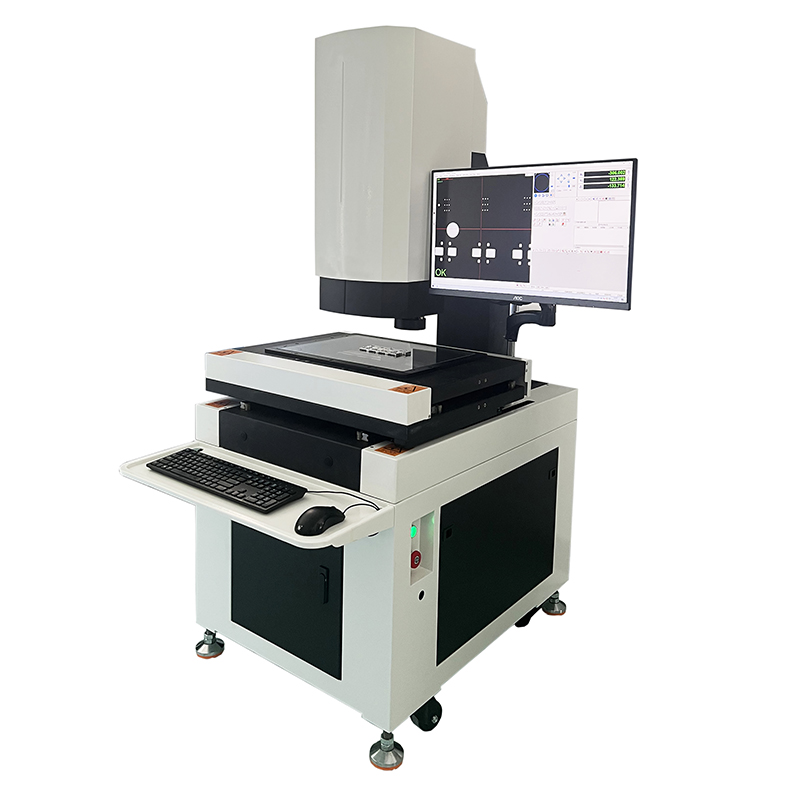

High Quality Thickness Tester - Semi-automatic PPG Thickness Gauge – Handing

High Quality Thickness Tester - Semi-automatic PPG Thickness Gauge – Handing Detail:

The PPG is suitable for measuring the thickness of lithium batteries, as well as measuring other non-battery thin products. It uses stepper motors and sensors to drive, which makes the measurement more accurate.

2.1 Turn on the computer;

2.2 Power on the instrument;

2.3 Open the software;

2.4 Initialize the instrument and return to the origin;

2.5 Put the standard gauge block into the equipment for calibration

2.6 Start measuring.

3.1.Sensor: Open grating encoder.

3.2.Coating: Stoving varnish.

3.3.Material of parts: steel, grade 00 jinan blue marble.

3.4.Cover material: Steel and aluminum.

|

S/N |

Item |

Configration |

|

1 |

Effective test area |

L200mm × W150mm |

|

2 |

Thickness range |

0-30mm |

|

3 |

Working distance |

≥50mm |

|

4 |

Reading resolution |

0.0005mm |

|

5 |

Flatness of marble |

0.003mm |

|

6 |

Measurement error of one position |

Put a 5mm standard gauge block between the upper and lower pressure plates, repeat the test 10 times at the same position, and its fluctuation range is less than or equal to 0.003mm. |

|

7 |

Comprehensive measurement error |

A 5mm standard gauge block is placed between the upper and lower pressure plates, and the 9 points evenly distributed in the pressure plate are measured. The fluctuation range of the measured value of each test point minus the standard value is less than or equal to 0.01mm. |

|

8 |

Test pressure range |

500-2000g |

|

9 |

Pressure method |

Use weights to pressurize |

|

10 |

Work beat |

9 seconds |

|

11 |

GR&R |

<10% |

|

12 |

Transfer method |

Linear guide, screw, stepper motor |

|

13 |

Power |

12V/24v |

|

14 |

Operating environment |

Temperature:23℃±2℃ Humidity:30~80% |

|

Vibration:<0.002mm/s,<15Hz |

||

|

15 |

Weigh |

45kg |

|

16 |

***Other specifications of the machine can be customized. |

|

Are your products traceable? If so, how is it implemented?

Each of our equipment has the following information when it leaves the factory: production number, production date, inspector and other traceability information.

Who are your company’s suppliers?

Hiwin, TBI, KEYENCE, Renishaw, Panasonic, Hikvision, etc. are all our accessories suppliers.

How long is the service life of your products?

Our equipment has an average lifespan of 8-10 years.

Product detail pictures:

Related Product Guide:

Sticking for the belief of Creating items of front end of range and creating buddies with people today from all over the world, we normally put the interest of shoppers in the first place for High Quality Thickness Tester - Semi-automatic PPG Thickness Gauge – Handing , The product will supply to all over the world, such as: Sri Lanka, Ghana, Amsterdam, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top